Machineries

We have world’s best Benninger Slasher Indigo dye range from Germany, which is capable of doing colored bottoming/topping reactive colored denim/Sandwich/ plus very deep indigo shades.

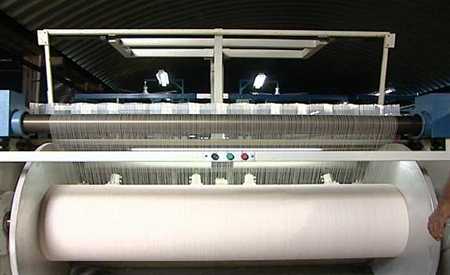

Most modern Weaving machine both in rapier and airjet version to get good productivity and to make trouble free fabric even if it is made with coarser slub or spandex. Picanol Omniplus 800 and gammax rapier from Belgium where used some special device as per our requirement which can help to produce better fabric than others mill though they used also same machine. The loom shed is totally humidified and temperature controlled with enough air circulation and sufficient pressure to help machine and yarn to make better fabric and always make the shed clean.

On the finishing side, we have Cibitex which is the most modern finishing range. It has mini Stenter to keep fabric width same without any variation. Sufficient brushing, singeing in both side, high quality skew device, bigger padder, sanforizer and compacting device to make the fabric more clean and maintain shrinkage properly.

Ranka Denim gives importance to inspection machines also. To control proper tension and easy handling Ranka uses most modern machines with conveyer belt with auto wrapping and packing. On the quality side, Ranka uses most modern and efficient lab instruments from Atlas UK which is operated by trained technicians. The verivide Light box, Spectophotometer, Rubbing tester, Washing Fastness, Tensile strength etc gives accurate results and helps to keep quality good and more consistent.

|

|